Timber Yard Tales

Timber Yard Tales – Stories, Tips, and Timber Know-How.

Welcome to Timber Yard Tales, where WBS Henderson brings you the heart, humour, and everyday wisdom of your local timber yard. Each week, Little Steve shares fresh stories, handy building tips, fun timber facts, and yes, the odd dodgy joke to keep things light.

Whether you’re a DIY weekend warrior, a seasoned builder, or just curious about what makes timber tick, this is where timber meets talk. No jargon, no hard hats required – just straight-up advice, explained in a way that feels like a yarn with a mate over the fence.

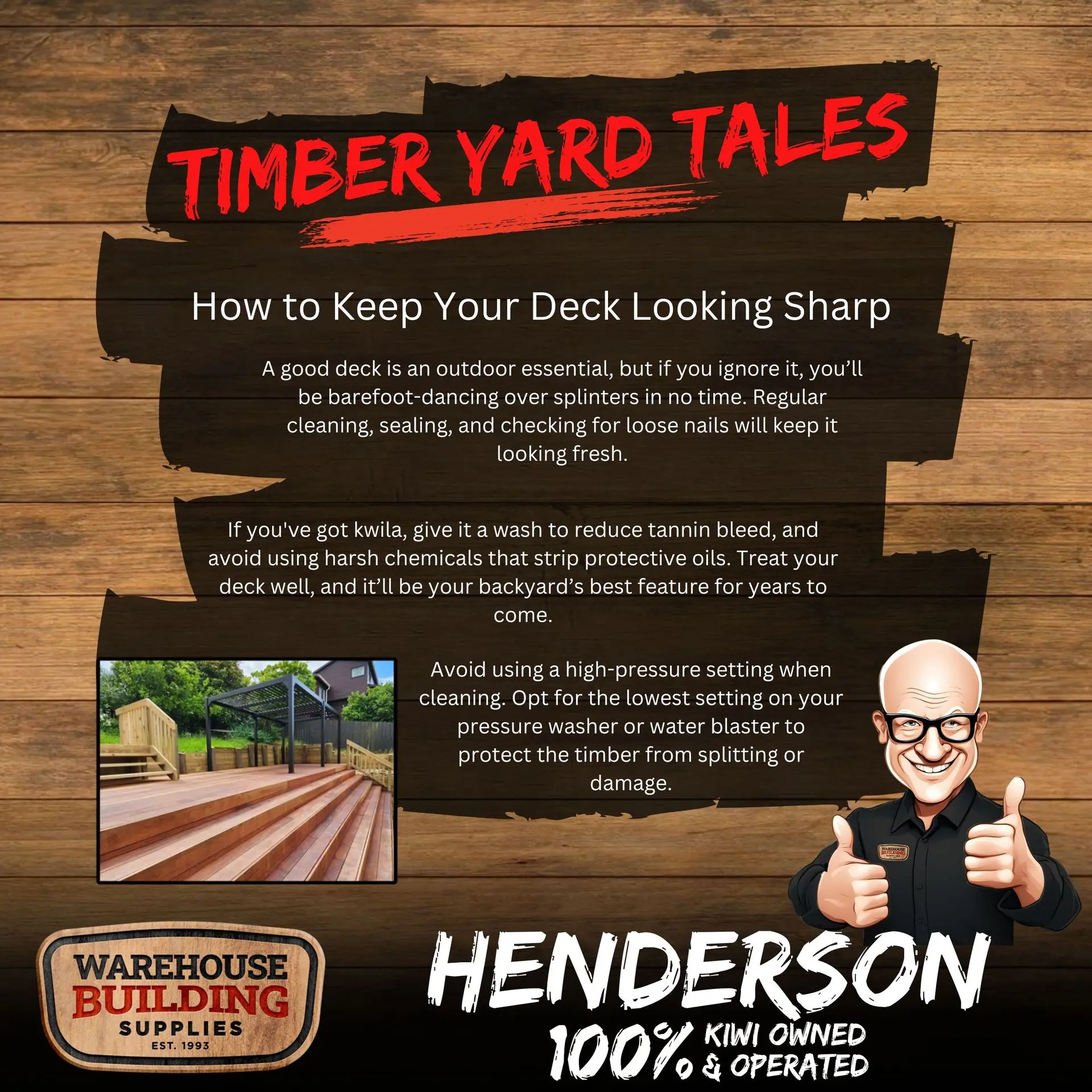

From cracking the code on H3.2 treated timber (perfect for outdoor projects) to spotting the difference between decking timber and fence palings, these weekly tales deliver practical timber knowledge with a cheeky smile.

And if a story sparks your next project, you don’t have to look far. Our WBS Henderson timber yard is stocked with decking, fencing, framing timber, and DIY building supplies – all at trade prices, open to the public.

So, grab a cuppa, have a laugh, and let’s get into the yarns …

Timber Yard Tales aren’t one-and-done. Some are worth re-reading, especially if you’re about to start a project. We’ve lined up the older stories below so you can catch up, refresh your memory, or just enjoy a laugh at the yard’s expense.

"That’s it for these yarns so far, but the timber yard never runs out of stories. Each week we’ll dive into another tale - the kind you don’t hear in a classroom, but you’ll remember when you’re out on the tools. From building tricks to timber myths, Little Steve’s always got another story up his sleeve."